| Availability: | |

|---|---|

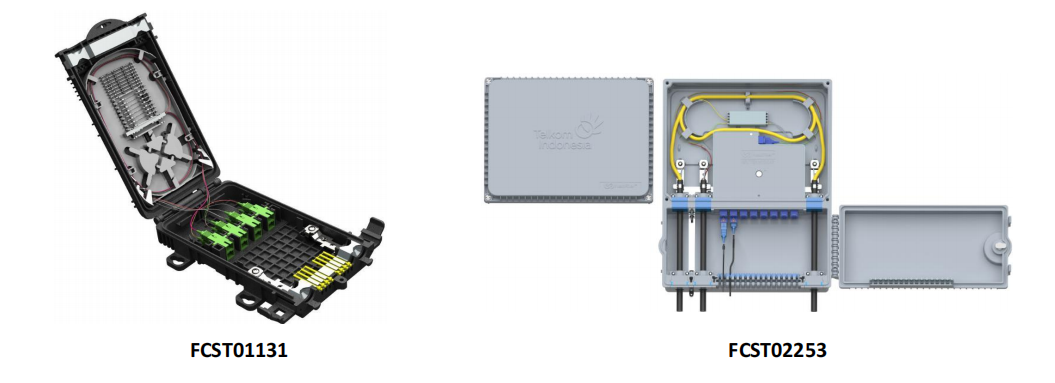

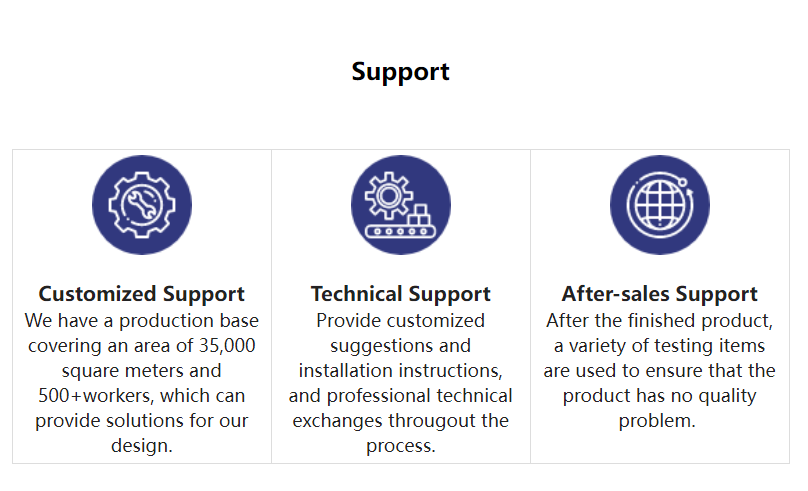

FCST01136

FCST

FCST01136

Product Advantages

l The Inline fiber closure is made of high-quality impact resistant plastic and has a standard user interface that can be re-opened.

l Can accommodate two 1x8 PLC splitter LGX module or steel tube type;

l Anti-ultraviolet,anti- impact and waterproof function;

l Unique flip board, flip angle ≥ 180 °, fusion area and distribution area is more obvious, reducing the cable crossing; Fiber optic cable can go in and out of the box without cut the cable.

Technical Parameters

l Optical fiber radius of curvature: ≥40mm Splice tray additional loss: ≤0.1dB.

l Temperature range: -40°C ~ +60°C.

l Anti side pressure: ≥2000N/10cm Impact resistance: ≥20N.m.

l Protection class: IP65.

Product Specifications

Construction | Description |

Max. Capacity | Single:96Cores |

Material | PP+GF |

Dimension (mm) | 285*175*90 |

Inlets/Outlets | 3/3 |

Installation | Pole/Aerial/Manhole |

Cable Port | 2pcs 8-20mm round ports,4pcs 5-16mm round cable |

Diameter Of Fiber Cable | Φ7mm~φ18mm |

Number Of Trays | 4 |

Capacity Of Tray | 24F |

Installation Procedure

Strip the outer jacket,inner jacket, loose tube off the cable, remove the oil filling paste inside the cable, keep the fiber length of 1-1.6m and the steel core of 30-50mm; insert feeder cable through the entry and lock with hoop, strength plate to fix the fiber core. The excess optical cable is coiled at the bottom, and the fused fiber optic cable is introduced into the fiber tray. Superfluous optical fiber cable will be fixed and stored at the bottom of the box, bring the cable into the splice tray. (See fig.1)

Lead the one end of the cable into the heat shrinkable tube on fusion splicing slots, heat appropriately to make the fiber and the protection tube integrated into one, and the protected optical fiber connector is snapped into the wiring groove; put on the PVC cover to prevent falling off. ( See fig. 2)

Packing List

Main body | 1 set |

L=400mm bare fiber buffer tube | 2 pcs |

Hoop / clamp | 2 pcs |

3x100 nylon tie | 10 pcs |

Heat shrinkable tube L=60mm | 2-72 pcs (configuration on demand) |

User manual | 1pc |

Design And Customization Services

l Provide service with whole process from blueprint to product to the customer.

l Meet customer’s requirement to customize logo in suitable place for existing product.

l Meet customer’s requirement to make reasonable modify and customization for existing product.

l The fiber optic enclosure rovide free design according to the requirement of customer after signed cooperative agreement.

Product Advantages

l The Inline fiber closure is made of high-quality impact resistant plastic and has a standard user interface that can be re-opened.

l Can accommodate two 1x8 PLC splitter LGX module or steel tube type;

l Anti-ultraviolet,anti- impact and waterproof function;

l Unique flip board, flip angle ≥ 180 °, fusion area and distribution area is more obvious, reducing the cable crossing; Fiber optic cable can go in and out of the box without cut the cable.

Technical Parameters

l Optical fiber radius of curvature: ≥40mm Splice tray additional loss: ≤0.1dB.

l Temperature range: -40°C ~ +60°C.

l Anti side pressure: ≥2000N/10cm Impact resistance: ≥20N.m.

l Protection class: IP65.

Product Specifications

Construction | Description |

Max. Capacity | Single:96Cores |

Material | PP+GF |

Dimension (mm) | 285*175*90 |

Inlets/Outlets | 3/3 |

Installation | Pole/Aerial/Manhole |

Cable Port | 2pcs 8-20mm round ports,4pcs 5-16mm round cable |

Diameter Of Fiber Cable | Φ7mm~φ18mm |

Number Of Trays | 4 |

Capacity Of Tray | 24F |

Installation Procedure

Strip the outer jacket,inner jacket, loose tube off the cable, remove the oil filling paste inside the cable, keep the fiber length of 1-1.6m and the steel core of 30-50mm; insert feeder cable through the entry and lock with hoop, strength plate to fix the fiber core. The excess optical cable is coiled at the bottom, and the fused fiber optic cable is introduced into the fiber tray. Superfluous optical fiber cable will be fixed and stored at the bottom of the box, bring the cable into the splice tray. (See fig.1)

Lead the one end of the cable into the heat shrinkable tube on fusion splicing slots, heat appropriately to make the fiber and the protection tube integrated into one, and the protected optical fiber connector is snapped into the wiring groove; put on the PVC cover to prevent falling off. ( See fig. 2)

Packing List

Main body | 1 set |

L=400mm bare fiber buffer tube | 2 pcs |

Hoop / clamp | 2 pcs |

3x100 nylon tie | 10 pcs |

Heat shrinkable tube L=60mm | 2-72 pcs (configuration on demand) |

User manual | 1pc |

Design And Customization Services

l Provide service with whole process from blueprint to product to the customer.

l Meet customer’s requirement to customize logo in suitable place for existing product.

l Meet customer’s requirement to make reasonable modify and customization for existing product.

l The fiber optic enclosure rovide free design according to the requirement of customer after signed cooperative agreement.